1) Have superior adhesion to metal and felt.

2) Dry to a semi-solid state.

3) Have long life expectancy.

Frequently Asked Questions About The

Direct-Action(tm) Pallet Valve

Revised 16:00, November 26th, 2003

Working with pallet valves that have become to thick (NEW).

Our felt is made from pure wool that is pounded and processed into its final thickness. Since we use a pallet valve that does not have a backing, the felt can expand in thickness over time when left freely alone. The solution is to store the felt in its shipping tube until needed. If all the valves from the tube are not used during assembly, the storage tube will need to have a spacer installed. To build a spacer, cut some cardboard to the need length and fold into a V shape and insert it into the storage tube to displace the valves removed. The felt expansion is simply a phenomena of the nature of compressed felt.

If some valves do expand, simply pound them with a board or other suitable object until they are 0.29" to 0.30" in thickness. They will retain there thickness out of the tube for several hours.

Note: The valves will retain their thickness once installed due to the tension of the magnet armature.

What coil resistances are available ?

70 ohm coils are the only resistance presently available. This resistance value meets the needs of higher wind pressure chests without taxing solid state relay control systems.

What is the difference between DA-M1 and DA-M2 ?

The DA-M1 is used for pallet valves 3/4" and smaller. The DA-M2 is for pallet valves larger then 3/4". The DA-M1 armature is restricted to 3/16" travel with a felt bumper. The DA-M2 armature is allowed to travel a full 3/8." Prompt and responsive pipe speech is improved by using the correct model pallet action.

What other adhesives can be used for pallet valves ?

Our experience has shown the 3M 08008 adhesive to provide superior performance over time. Any personal choice of adhesive should include the following properties.

1) Have superior adhesion to metal and felt.

2) Dry to a semi-solid state.

3) Have long life expectancy.

Customers have used the DA-M1 with 3/4" pallet valve on 17 inches wind pressure and a supply of 15 VDC. We recommend that all customers perform their own wind pressure tests to make pressure determinations. Many factors influence these tests, and what works well for one customer, may not work for another.

Direct-Action pressure test results

Do I need an expansion chamber ?

NO. The patented angular motion of the armature removes the necessity for any further design modifications to a standard toehole. During opening and closing of the pallet valve, air velocity if gradually changed from none to full air flow. The valve moves away from the toehole at an angle that does not lend itself to the usual popping or bounce characteristics associated with other magnet action designs.

The pallet action with a 3/4" pallet valve was designed to reiterate in a 60 ms cycle time. This amount of cycle time greatly assists voicers when working with low wind pressure pipework. The need for nicking is reduced, reed pipes speak more promtly, and valve popping is eliminated.

When properly installed and adjusted the Direct Action Pallet will not bounce. However, the Direct Action Pallet valve can bounce if installation techniques are not completely followed.

Check both armature and pallet spring tensions. Most often the spring tension is too light.

Pallet valve travel may be to great for pallet valve size. Reduce travel by bending frame toward valve.

Pallet valve may be adhered to armature in wrong position. See 'Distance to toehole center' table in instruction sheet.

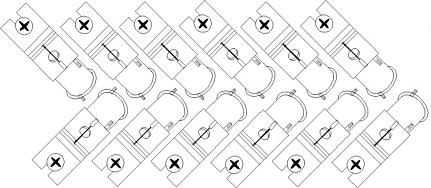

How do I fit more magnets in the same place ?

Mount the Direct Action pallet valve magnets in an angle when set in a rows.

Why do Pallet Valves stick to the toeboard ?

If a pallet valve sticks to the toeboard, it is because either the leather has to much fat in it, or the wood toeboard finish has adhesive properties. Ordinary talc power place on the pallet valve and gently rubbed in to the leather will permanently correct this problem.